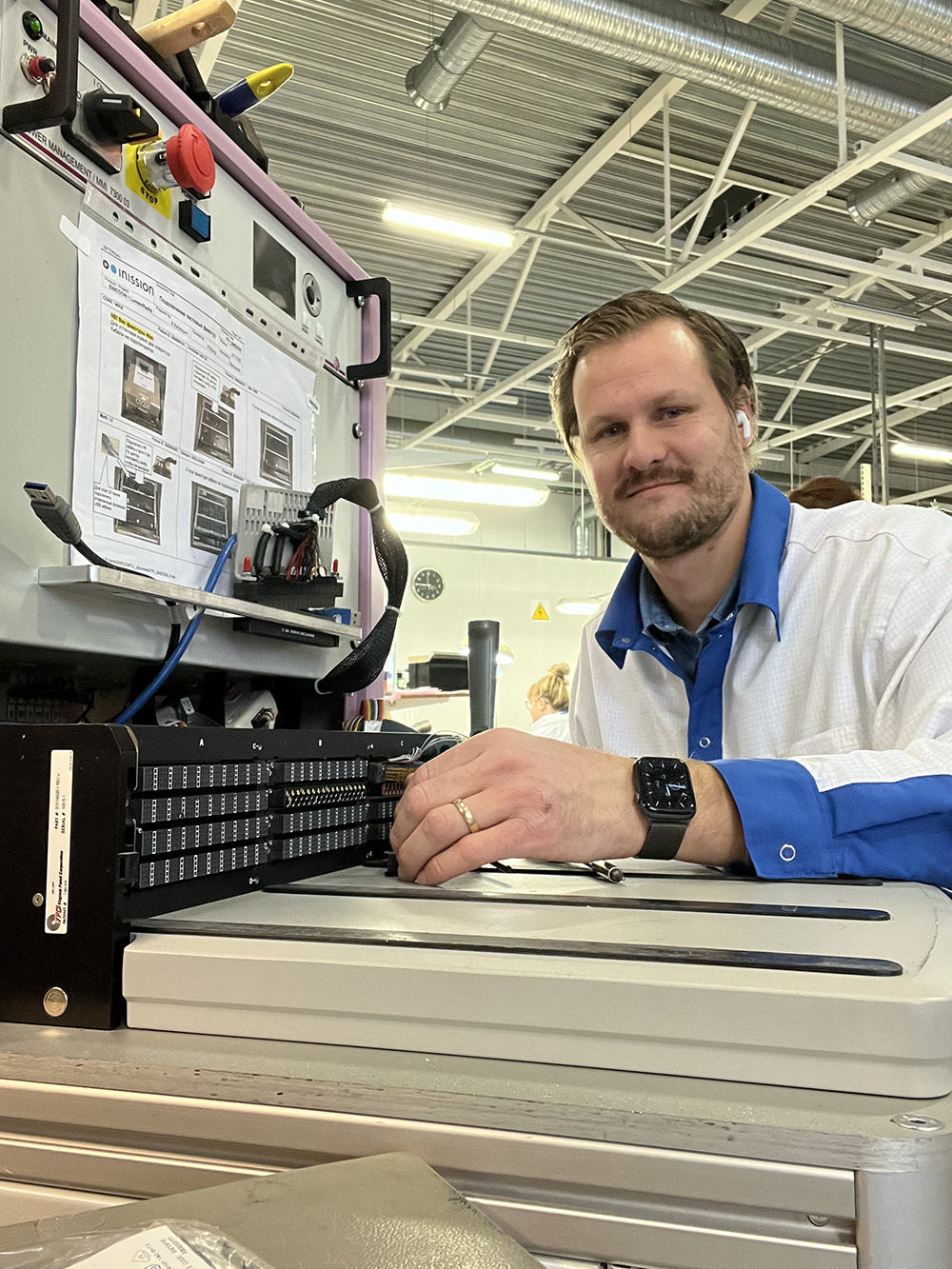

Production

.png?width=1500&height=1000&name=Fixture%20Wiring%20(1).png)

Aerospace Testing

This project focuses on developing a versatile and cost-effective test system for the aerospace industry, designed to meet the evolving needs of R&D and production environments. The system features a rack-mounted, fully modular PXI-based design that can handle over 2500 channels with high voltages up to +300V, supporting sample speeds up to 1.8MS/s. By incorporating a common Virginia Panel Corporation (VPC) interface, the system ensures flexibility, allowing for easy integration of new or modified products. Additionally, the system is paired with QESTIT's object-oriented framework QATS, making it highly scalable and adaptable to a wide range of testing requirements.

Engineered for today's and tomorrow's products

This is a standard configuration for aerospace testing which uses custom made test platform. The system is primarily designed for R&D testing but can be repurposed for production testing when the product enters the production phase. This reduces cost for our customers, while not compromising on system quality.

.png?width=1500&height=1000&name=Test%20Fixture%20Open%20(1).png)

To ensure that the test system will be suitable for both today’s and tomorrow’s products, a concept for a large variety of instruments is linked in a common connection interface (as seen in the bottom of the image above). This interface (a Virginia Panel Corporation [VPC] interface) is attached directly to a UUT or onto a smaller test fixture which can handle multiple products. This means that existing products can be changed or entirely new products can be created, that can still be used with the same test fixture provided they use the same VPC interface to communicate with the test station.

In addition to designing test stations, we also design or can assist customers with designing test fixtures that communicate using VPC interfaces. One such example is currently used in the satellite industry in Sweden for testing parts designed to resist the strain of being in space. The fixture uses common connectors (such as D-sub) to interface with UUTs. 3D printed components for holding UUTs can be easily and cheaply replaced by QESTIT or in-house. This reduces the cost of adapting fixtures to developing products. All of our fixtures use standard components and are delivered with document packs describing product assembly and maintenance requirements.

Pictures from the project

.png?width=1500&height=1000&name=Test%20Fixture%20Open%20(1).png)

.png?width=1500&height=1000&name=Fixture%20Wiring%20(1).png)

Using QATS to ensure scalability and flexibility in the testing system

This design is then coupled with QESTIT's object oriented framework QATS to ensure scalability and flexibility in the test system. The system was designed with reusable software modules developed using LabVIEW. Modules can be added or removed as needed (using GUIs and XML config files) making the system flexible and capable of handling a wide array of products. Furthermore, it makes integrating new products/features a simple process.

All channels of the test system can be calibrated and validated using a custom made loop back adapter. The loop back adapter can easily be connected to the test system using the Virginia Panel Corporation (VPC) interface. This means hardware systems can be tested before delivery while still ensuring accuracy and repeatability.

Summary

In summary any Aerospace test systems we produce are reliable and have high throughput. They can be easily calibrated when needed, with a universal VPC interface for connecting to different products. The software is modular and configurable, with new products or variants being easy to add.