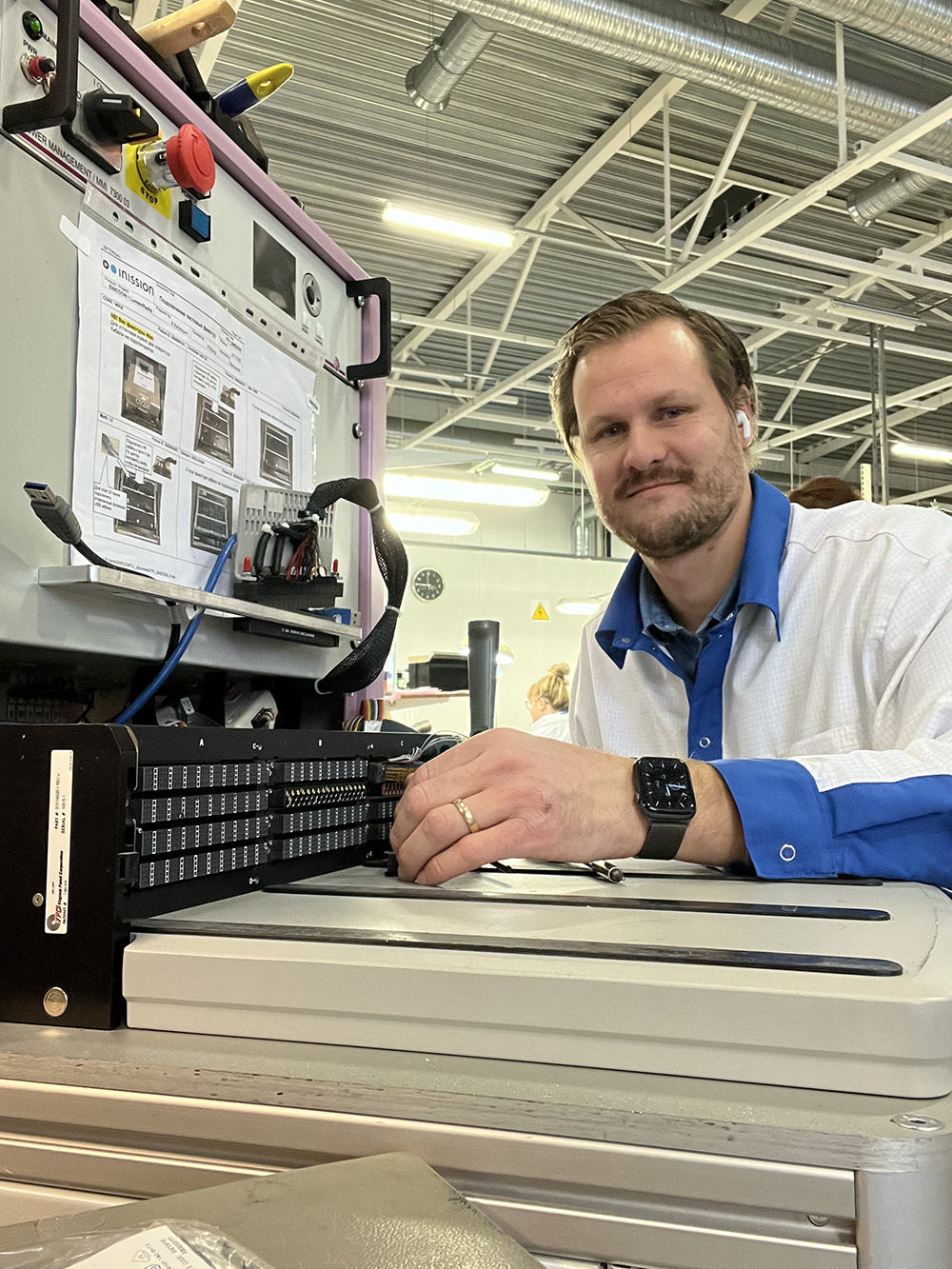

QESTIT helped Backer to develop a mobile test system designed to meet the rigorous demands of truck heater testing. The project addressed challenges such as handling high voltages and currents, integrating LIN communication, and ensuring coolant flow during testing to prevent overheating. With operator safety and robust data logging as top priorities, the system served as a critical component in Backer’s End of Line (EOL) test suite. This custom-built solution provided a safe, efficient, and adaptable platform to calibrate and validate heaters before release.

Ensuring Safety and Optimizing Heater Performance

This system was a simple but important part of a larger test routine conducted by Backer for a truck heater. It was integrated with other components to form an End Of Line (EOL) test suite, checking the heater's safety and performance. This system was a unique challenge, as it was not a typical EOL test system and was used (in part) to calibrate units to perform better before release.