Production

Control & Monitoring System

Chalmers University's Division of Energy Technology was seeking a robust system to support their groundbreaking research in power generation. The goal was to create a solution capable of monitoring and saving data from various sensors, while also controlling industrial equipment for experimental purposes. To address this, QESTIT upgraded and customized an existing program, working closely with the research team to ensure the system met their specific needs. The collaborative approach resulted in an enhanced system that not only improved data management but also streamlined the research process, allowing Chalmers to continue their work without delays.

Driving Innovation Through System Upgrades and Expansion

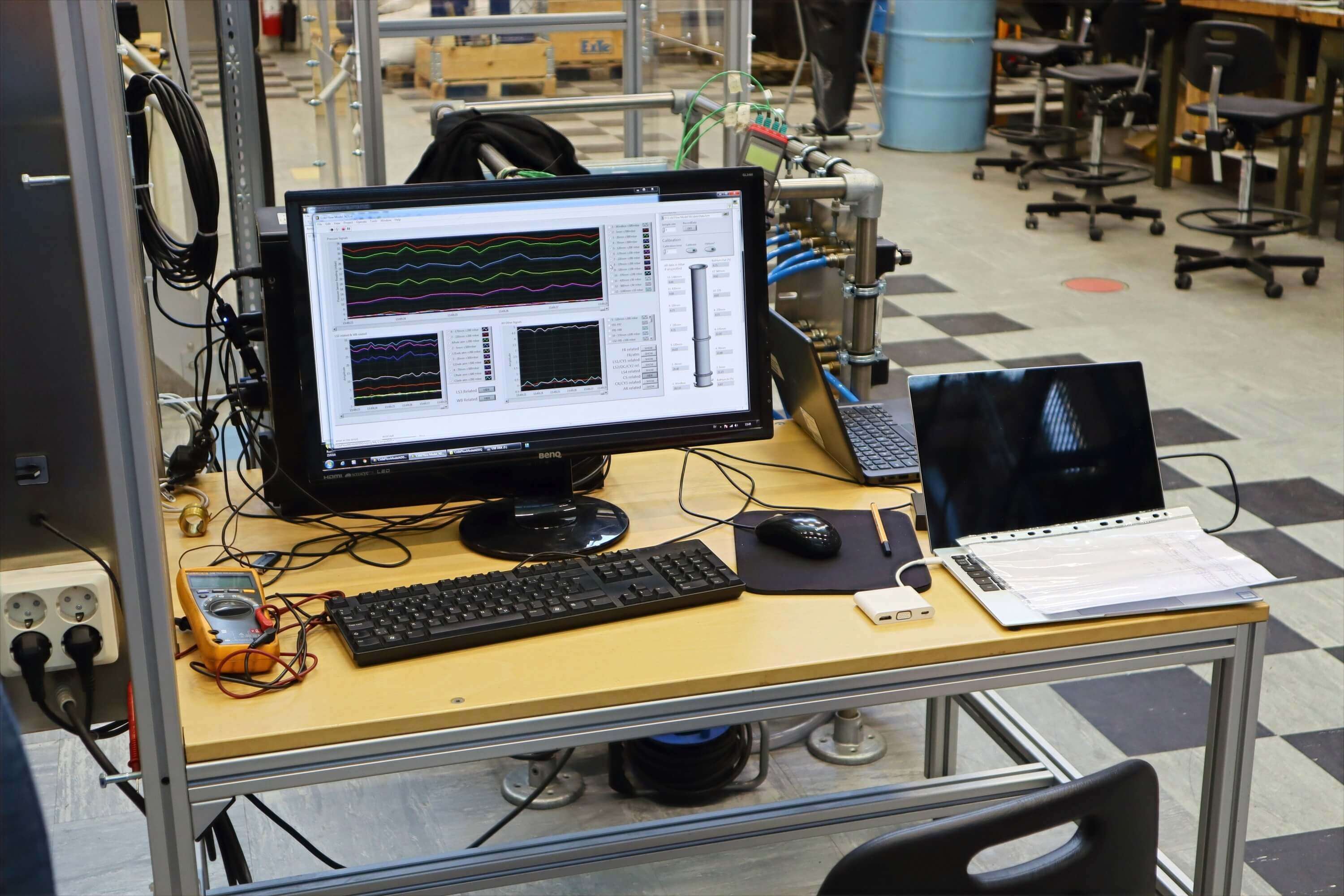

The Division of Energy Technology at Chalmers University needed a system to test pumping gas through various powdered solids (for example sand). This system needed to communicate with instruments used to control gas flow through the chamber. It also needed to monitor the pressure and temperature throughout the system and calculate several other readings (such as absolute pressure) in real time. All of the data recorded needed to be saved in an understandable format for analysis later in the project.

QESTIT worked on-site directly with the research staff that would be using the program. Users were able to give direct feedback to the system designers during the development phase of the project and customize the final product to what they needed. This also helped researchers to expand their LabVIEW knowledge, gain insight into the development process and receive advice on how to maintain and expand the program in the future.

The delivered system was an upgrade and expansion of an existing system developed by Chalmers University staff. Utilizing our expertise in LabVIEW, we developed a solution with a more responsive user interface including several new features for displaying data. The project was completed and installed within two weeks, allowing researchers to continue their projects without major delays.

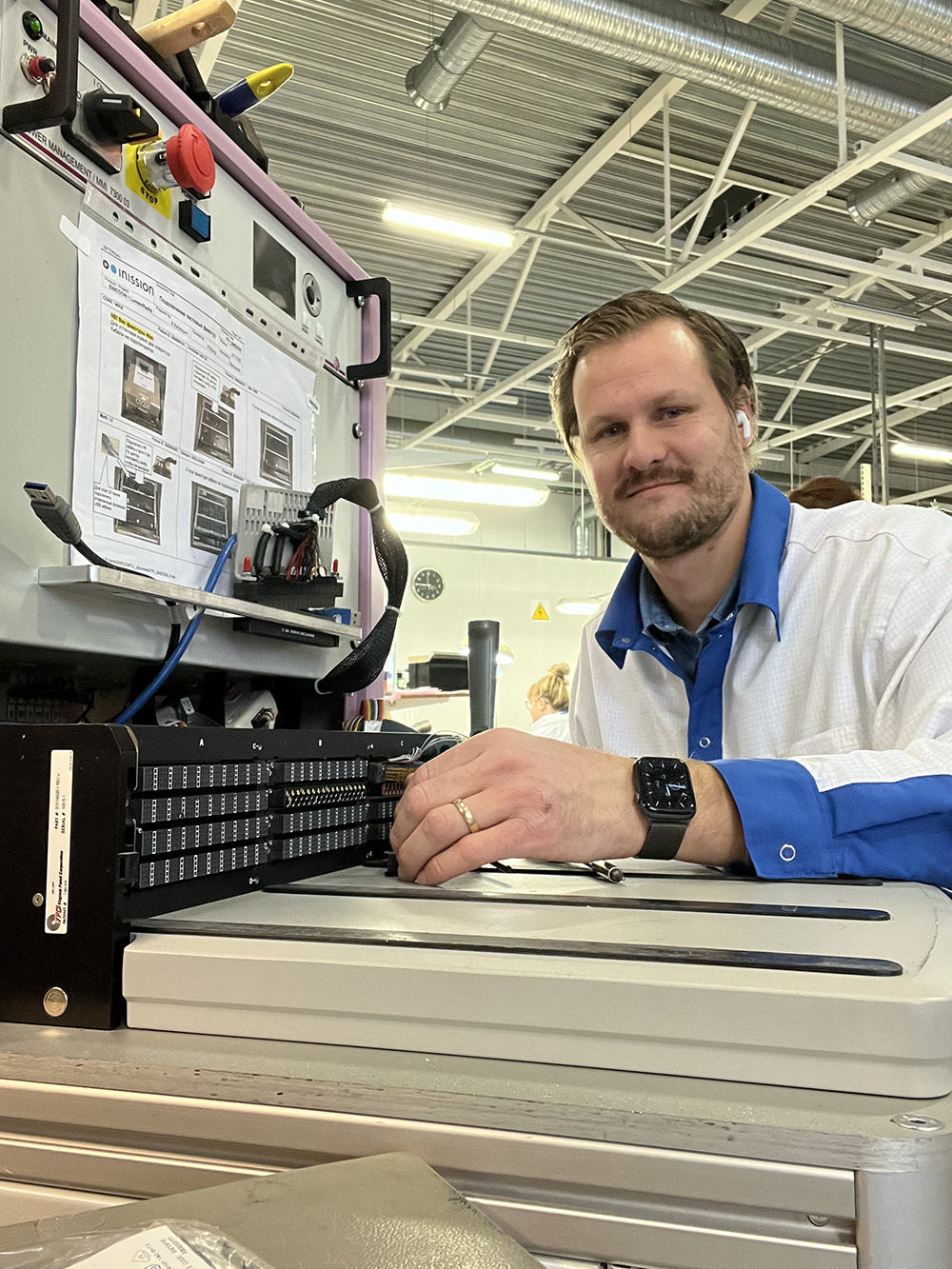

Pictures from the project

Hardware Installation and Support

Aside from the software development, QESTIT also assisted in installing additional hardware for the system. After creating a specification, we recommended hardware to be purchased by Chalmers to monitor all the sensors for the system. We then assisted with the installation of the hardware (which in this case was a CompactDAQ Chassis with NI 9205 modules)

The QESTIT Systems team employs two certified LabVIEW architects with practical experience that stretches over 35 years when combined. We assist on developing new systems, improving existing systems and providing LabVIEW training or certifications. We have developed custom in-house LabVIEW courses for our G# Framework and run NI certified courses at our offices in Gothenburg/Stockholm.

A seamless collaboration from beginning to end

“ We feel that the collaboration has worked very well!QESTIT has been very good at listening, informing and applying our desired solutions. ”

Rustan Hvitt

Research engineerSummary

Chalmers received an improved test system with additional features added by the Systems Team. It collects all sensor information and saves it in a custom file which can be opened in excel for easy analysis.

Chalmers University's Division of Energy Technology

What does they do?

The Division of Energy Technology at Chalmers University focuses on developing resource-efficient, sustainable technologies for energy, transportation, and heavy industries.

what is their purpose?

Their research combines energy conversion processes with a systems-level approach to improve efficiency and reduce environmental impacts across various sectors.