Nibe developed an innovative Human Machine Interface (HMI) device featuring a touch screen for user input and information display. However, testing this physical interface posed a challenge, especially when considering the need to ensure operator safety and maintain fast cycle times with units secured in a test fixture.

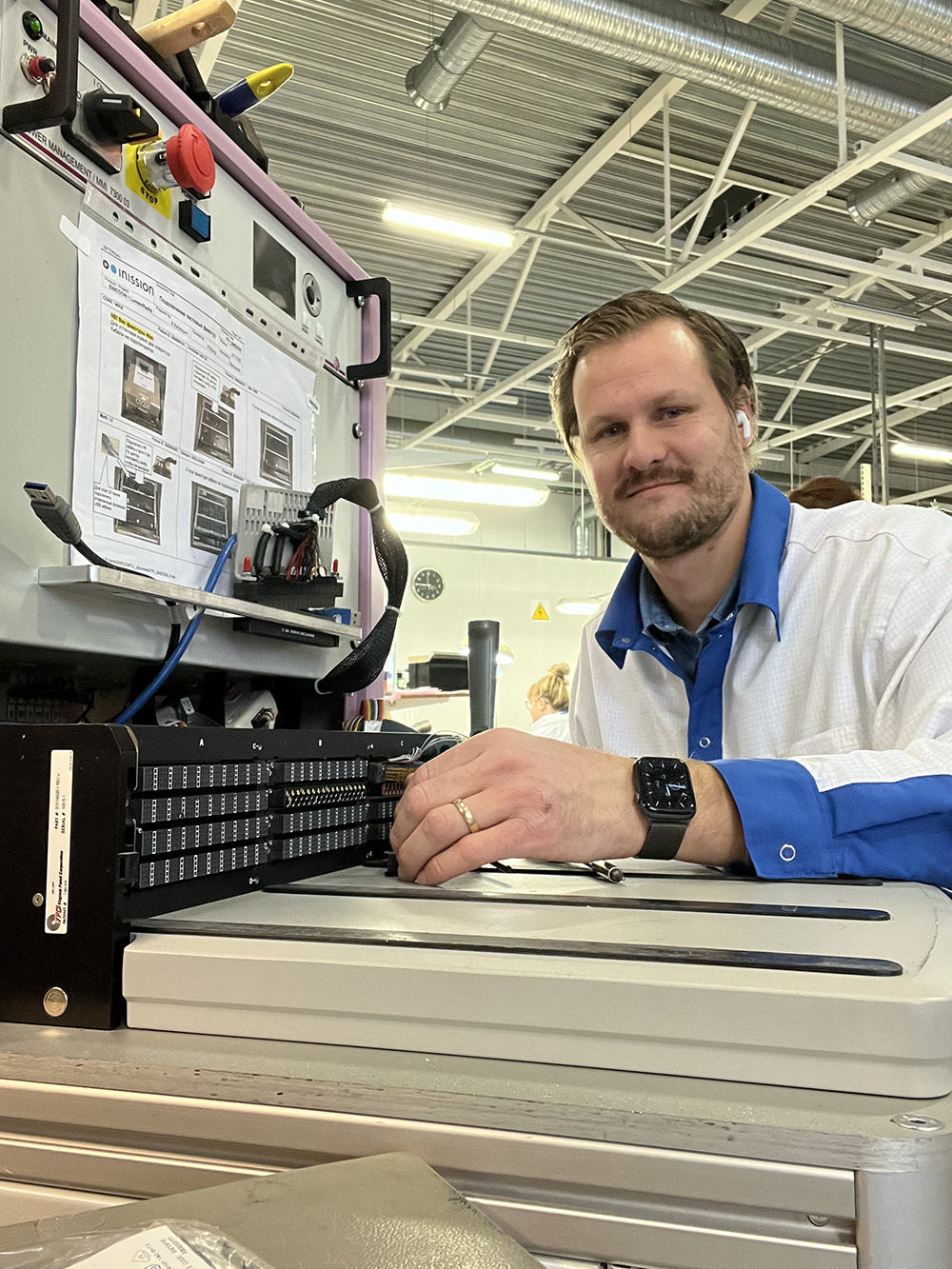

To address this, QESTIT engineered a specialized test fixture compatible with Nibe's existing Test stations. This fixture integrated a camera vision system and linear actuators, enabling precise reading and pressing of the HMI device under test (UUT).

Complete HMI Functionality Through Advanced Fixture Integration

This test fixture is similar to other fixtures we have produced for Nibe and uses the same hardware to record measurement results.

The main challenge of this project was constructing a system which could verify several HMI features, while the HMI unit was placed inside of the fixture. The features could not be verified in a conventional way - for example by reading test point voltage - and were often based on physical stimuli (like touch or sound). These included:

-

Verifying the screen displays different colors

-

Verifying the display backlighting in various conditions

-

Verifying the RF and Zigbee capability of the HMI device

-

Verifying buttons on the HMI worked when pressed

-

Verifying the UUT outputted a sound at the correct point during testing