Production

Modular PCB Test System

Nibe, a leader in consumer electronics, encountered a growing challenge as they managed a wide array of PCBAs (Printed Circuit Board Assemblies) across their product range. With numerous configurations and versions, the process of creating and switching between tests became increasingly slow and confusing. This inefficiency was further compounded by result data being scattered across multiple storage solutions, driving up development and maintenance costs.

To tackle this problem, QESTIT introduced the their software platform QATS, integrated with a modular test station. This solution enables Nibe to quickly generate, iterate, and seamlessly switch between different test setups, significantly improving efficiency. Additionally, by consolidating all result data in a unified cloud solution, Nibe can now streamline operations, reduce costs, and maintain a more organized and agile testing process.

A Modular Approach with NI PXI(e) and VPC Interfaces

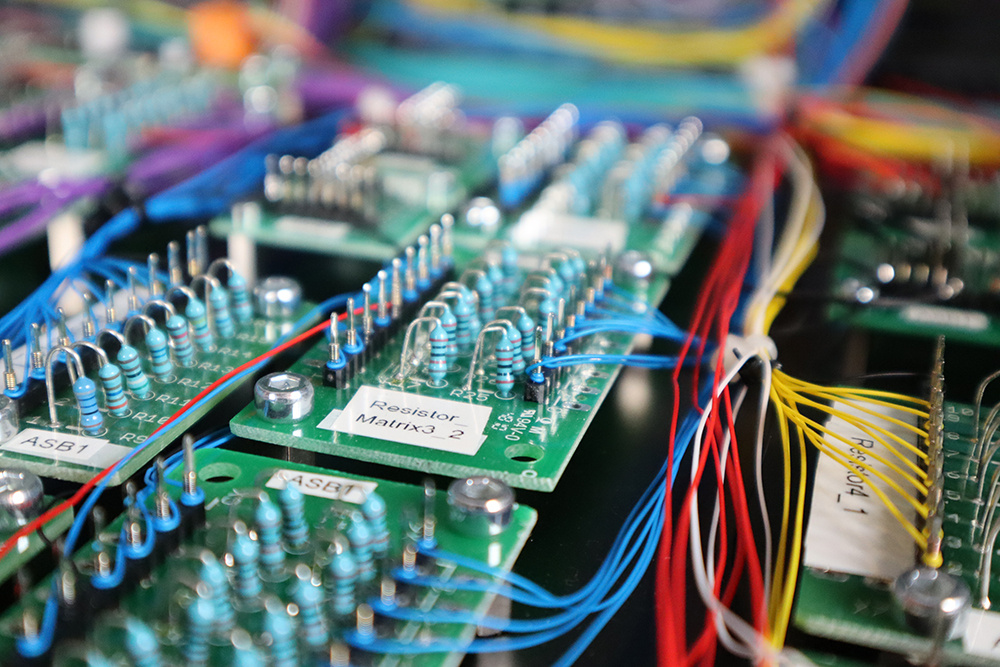

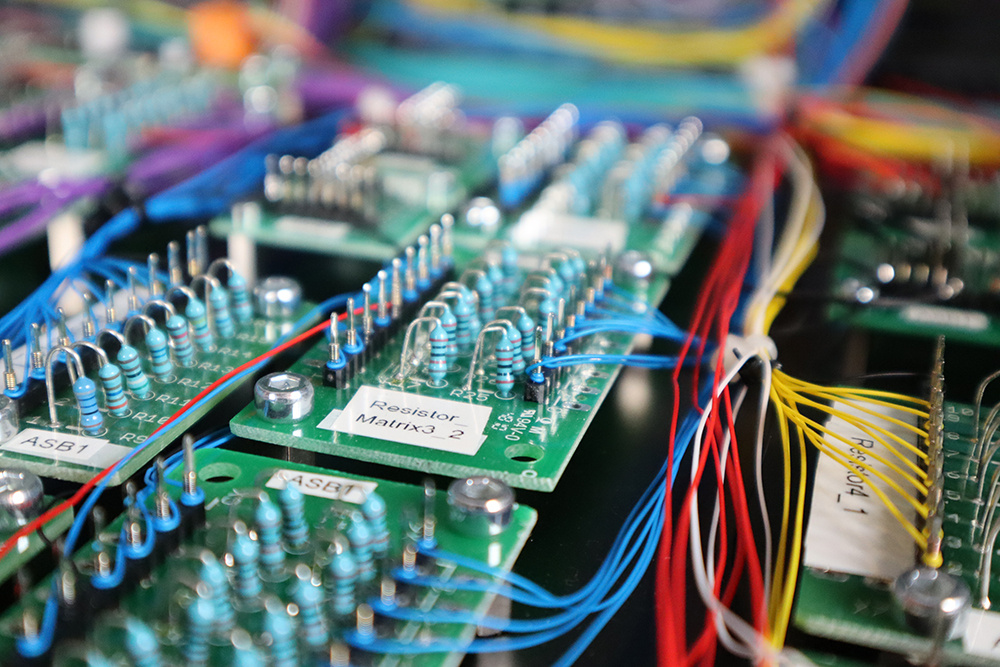

One of the main challenges involved with the project was that each PCBA required a different hardware interface. The connection points to the Unit Under Test (UUT) changed position and pin size depending on the product. Furthermore, the hardware needed to capture different types of data also needed to change between tests. This change had to be accomplished quickly and simply as possible.

A NI PXI(e) based solution was the ideal approach, as it's large size and flexibility allowed for many types of instruments. To simplify the process of operators connecting to the PXI, a Virginia Panel Corporation (VPC) interface was attached to the test station. Sub-fixtures can then be attached to the VPC interface with only a single lever. This future proofs the system, as new sub-fixtures can be developed which attach onto the same VPC interface and integrated quickly with the hardware/software.

All channels of the test system are calibrated and validated using a custom-made loop back adapter. The loop back adapter can easily be connected to the test system using the Virginia Panel Corporation (VPC) interface. This means hardware systems can be tested before delivery while still ensuring accuracy and repeatability. We can recommend regular calibration dates for your system and provide the tools you need to complete it.

Each PCBA type then receives a unique sub-fixture with its own set of connectors to the UUT. These sub-fixtures follow a standardized design that operators can easily open and close. The fixture can be locked, ensuring safety. Maintenance or changes can be made on this sub-fixture without having to take the existing test station offline.

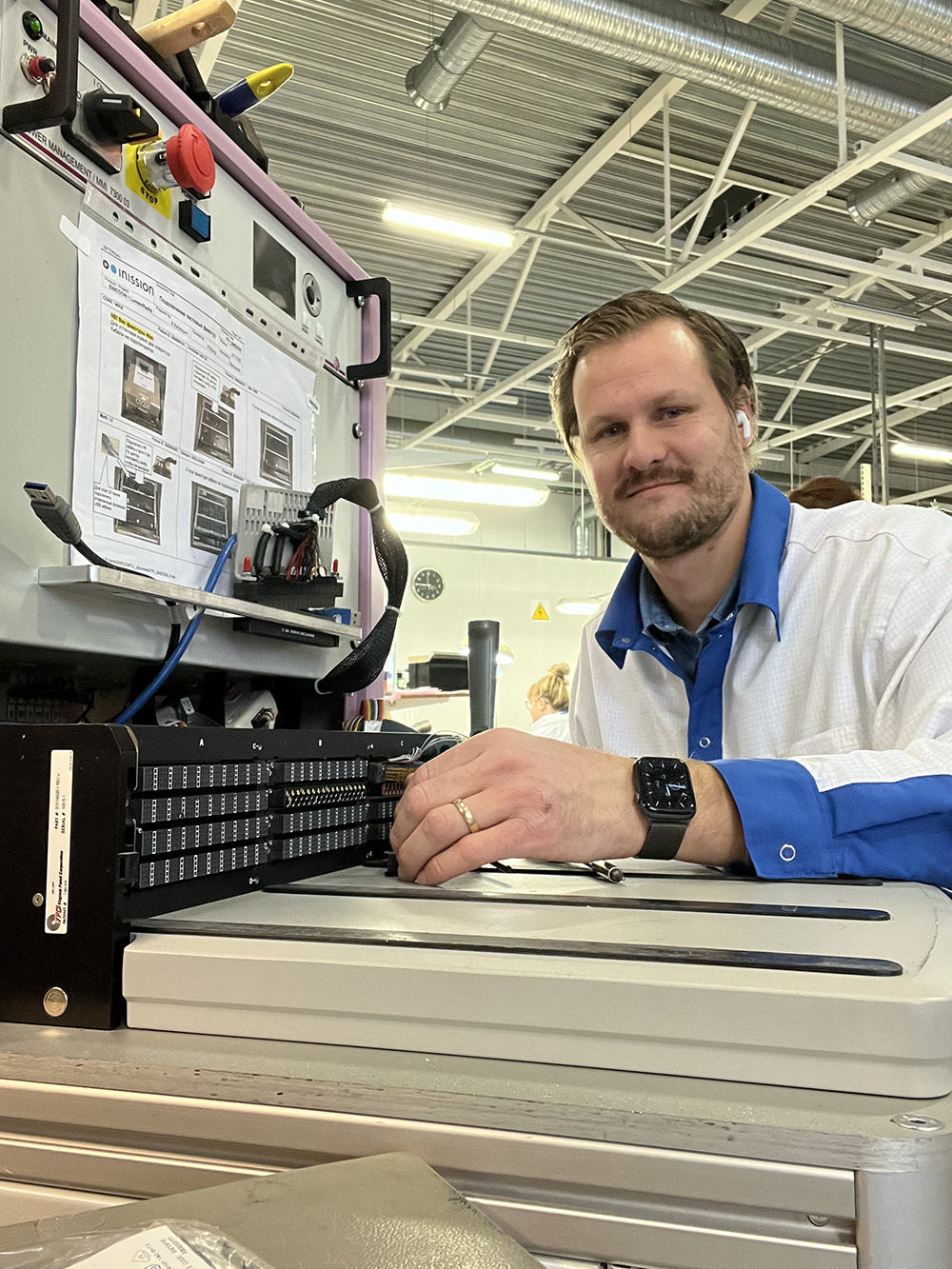

Pictures from the project

A flexible and user-friendly software for various product tests

While hardware is essential to a test system, the test software is equally or more important. Test software needs to be quick to develop, easy to maintain and straightforward to use. Thankfully, our software is all of those things!

The system's software is built in LabVIEW in our QATS platform. We use this object oriented framework to ensure scalability and flexibility in the test system. We use a reusable set of software modules that can be added or removed as needed. This makes the system flexible and capable of handling a wide array of products. It makes integrating new products/features a simple process.

All of our tests are launched from a single program installed onto the computer as an executable file. Operators can switch between test sequences quickly using our simple user interfaces that display results in real time.

Trusted for Competence and Clear Communication

“ We use QESTIT because we need your competence and experience. We also appreciate the straightforward and simple communication in our projects.”

Staffan Gustafsson

Project Manager, NibeSimplifying Data Management

Nibe standardized result management using our result management software QRM. QRM is a web based result management system that stores and analyzes test results. QRM data consists of not only the measurement data but also additional information such as the traceability of the station/equipment used, configuration version and additional Unit Under Test (UUT) information. Nibe opted for storing all result data on our QESTIT servers. We securely store and backup your test data freeing space on your servers and time you would spend managing large quantities of data.

Nibe also uses QRM to perform data analysis (such as 6 sigma calculations). This helps them find common failures, increase manufacturing time and improve their products. Often the solutions to optimizing a production process are simple once you have enough data available to make decisions.

Summary

In summary Nibe received a complete test system which not only reliably verifies assembled products but also stores, organizes and analyses result data. By using modular hardware and software, products can be changed easily in a matter of minuets. By outsourcing test development to an experienced team, Nibe saved resources by reducing development time, complexity and system setup time.

This modular PCBA system is currently in use, with Nibe using several stations for PCBA testing

NIBE

What does NIBE do?

NIBE develops and manufactures intelligent and energy-efficient solutions for indoor comfort in various types of buildings.

How?

They combine renewable energy with new intelligent technology and offer products for heating, cooling, ventilation, and hot water. NIBE aims to create energy-efficient products that reduce the climate footprint.

What does it result in?

It results in improved indoor comfort with low environmental impact and contributes to the global transition to a more sustainable society.