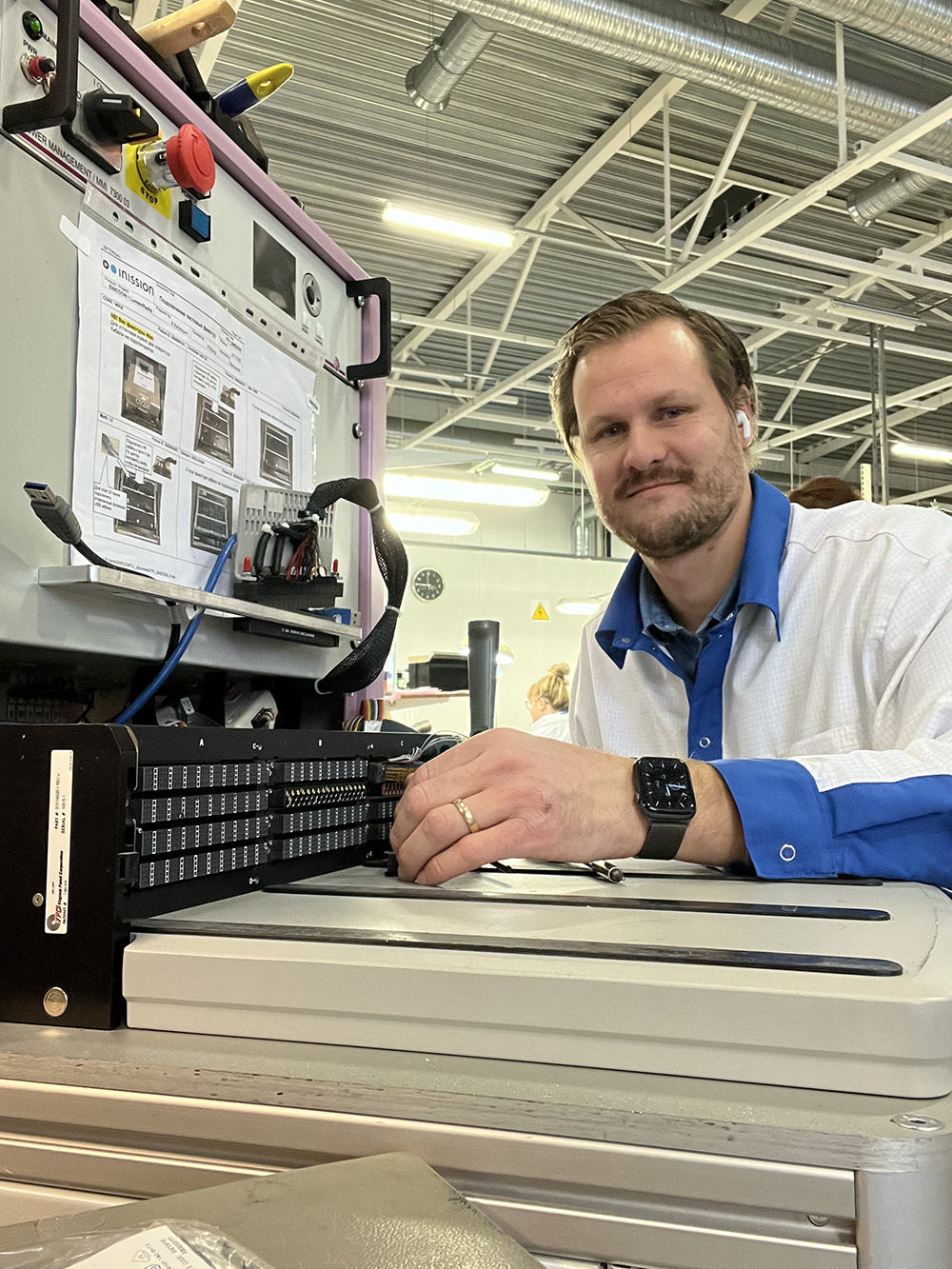

Production

Common Questions about QRM

QRM (Quality Result Management) is a platform for collecting, storing, and analyzing test results from production environments. It gives teams full visibility into product quality, test performance, and helping them make data-driven decisions faster.

QRM supports a wide range of data sources, including databases, text files, Excel files, JSON files, and more. It can also aggregate results from multiple test stations, processes, and manufacturing lines.

QRM is designed for flexible integration. It works with common test frameworks such as LabVIEW, TestStand, .NET, Python, and other custom applications. Data is sent to a centralized server via clients, and the system can be deployed locally, on-premise, or in the cloud depending on your IT requirements.

QRM provides powerful built-in analytics tools, including yield analysis, SPC charts, capability analysis, statistical trends and Measurement Systems Analysis. Users can generate detailed test reports for specific products, batches, stations, or time periods, all through an intuitive web interface.

QRM automatically logs detailed metadata about each test, such as test station, software version, operator, hardware configuration, and product identifiers. This ensures full traceability and enables teams to track changes over time and quickly identify when and where variations occur.

Yes. QRM is built for scalability and multi-site environments. Test results from different factories or test stations can be viewed in real time, regardless of geographical location, ensuring consistent quality oversight across the entire organization.

Test results appear in QRM almost immediately after a test is completed. Yield, failure statistics, and trend analyses update in real time, enabling engineers and managers to diagnose problems and take corrective actions without delays.

QRM features an intuitive web interface with clear dashboards, charts, and data filters. Most users require minimal training to get started, and the system is designed so both engineers and non-technical stakeholders can easily navigate and interpret results.

We provide full implementation support, including consultation on system setup, integration assistance, best-practice guidance, and user training. Our team can help tailor the deployment to your environment and ensure a smooth transition.

QRM is highly adaptable. It supports small R&D teams, large-scale production facilities, and multi-factory setups. You can start small and expand as your needs grow, with options for different data volumes, performance requirements, and deployment models.

QRM also provides an API (Application Programming Interface) which enables easy data exchange with other software applications in your company.

QRM fits any industry where product quality and traceability are crucial, such as electronics manufacturing, automotive, telecom, medtech, industrial automation, and high-volume production lines.

QRM includes role-based access control, allowing administrators to define what each user can view and modify. All communication between clients and the server is secured, and the system can be deployed within your own network to meet internal security and compliance requirements.