Production

.jpg?width=3000&height=2339&name=IMG_0112_edited%20(1).jpg)

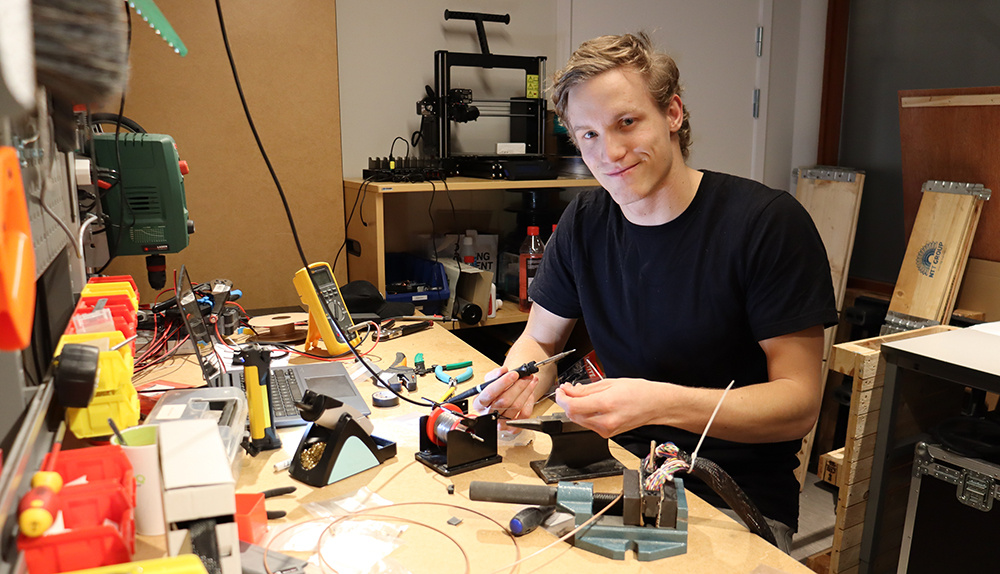

End of Line Test System

EOL testing is used at the end of the production process to ensure that each product functions as intended before it leaves the factory.

Provide Your Information

MEETING THE REQUIREMENTS SPECIFICATION

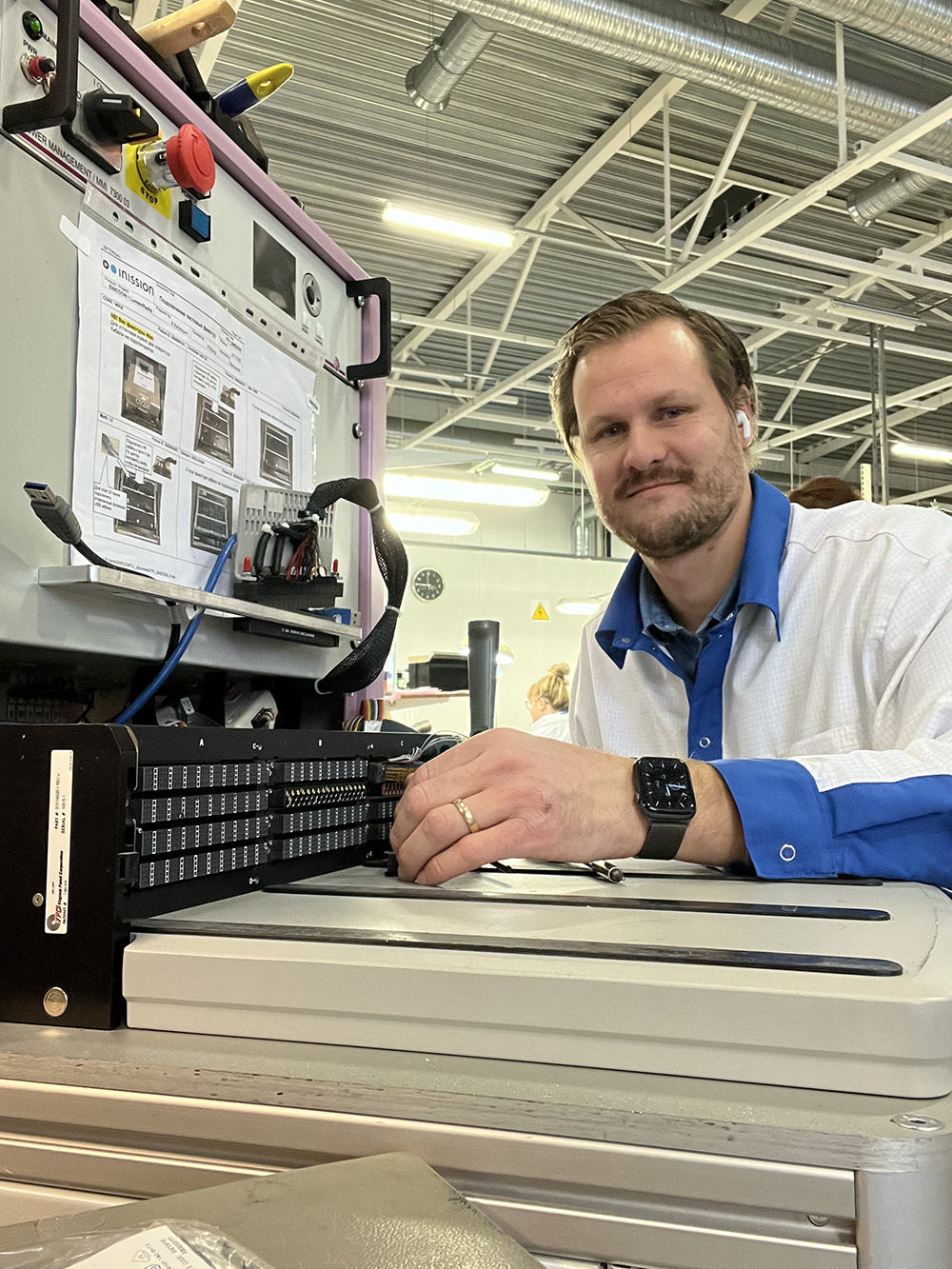

An EOL (End of Line) test system is deployed at the final stage of production to verify that the product functions as intended before leaving the factory. Its primary goal is to identify any non-functional units.

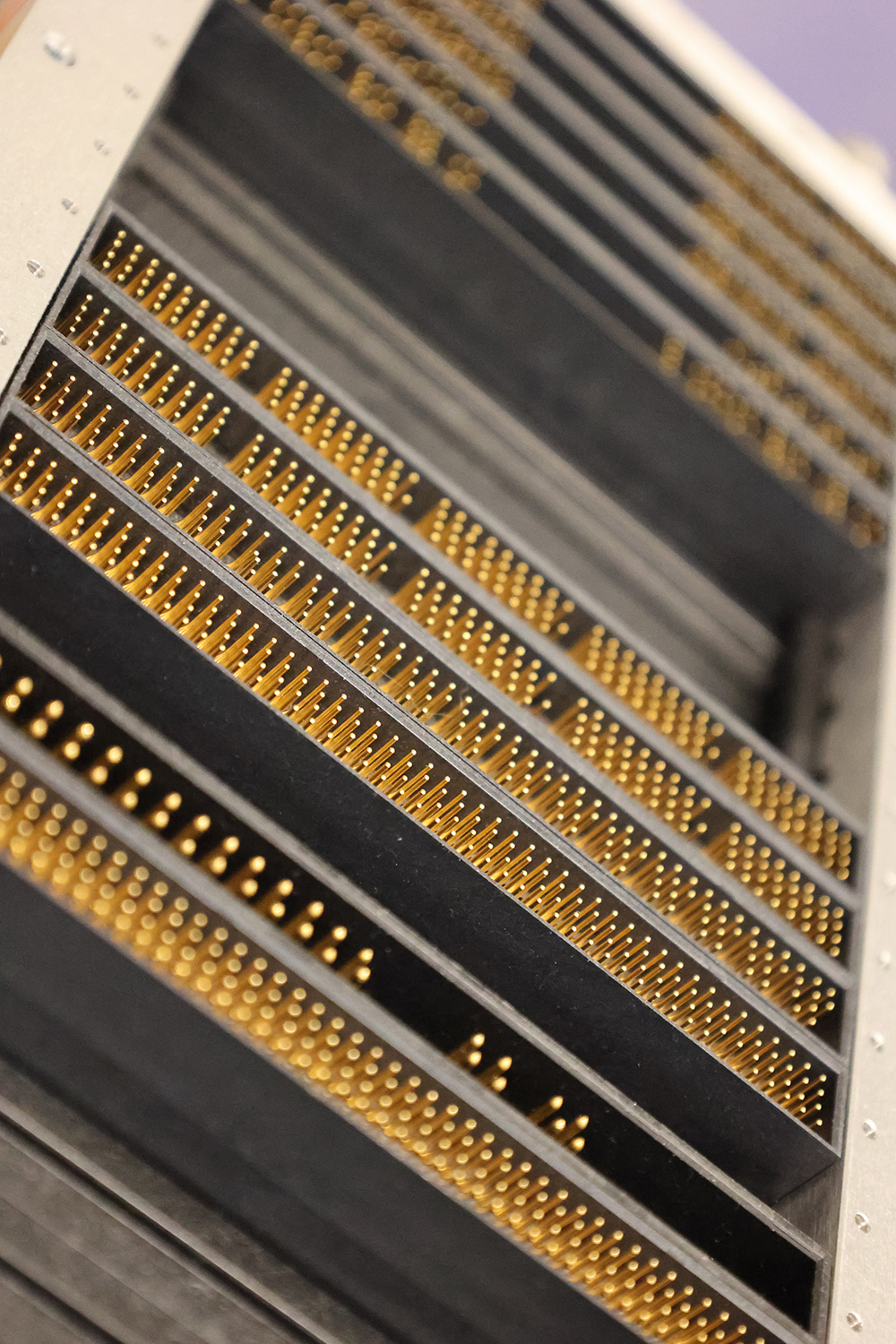

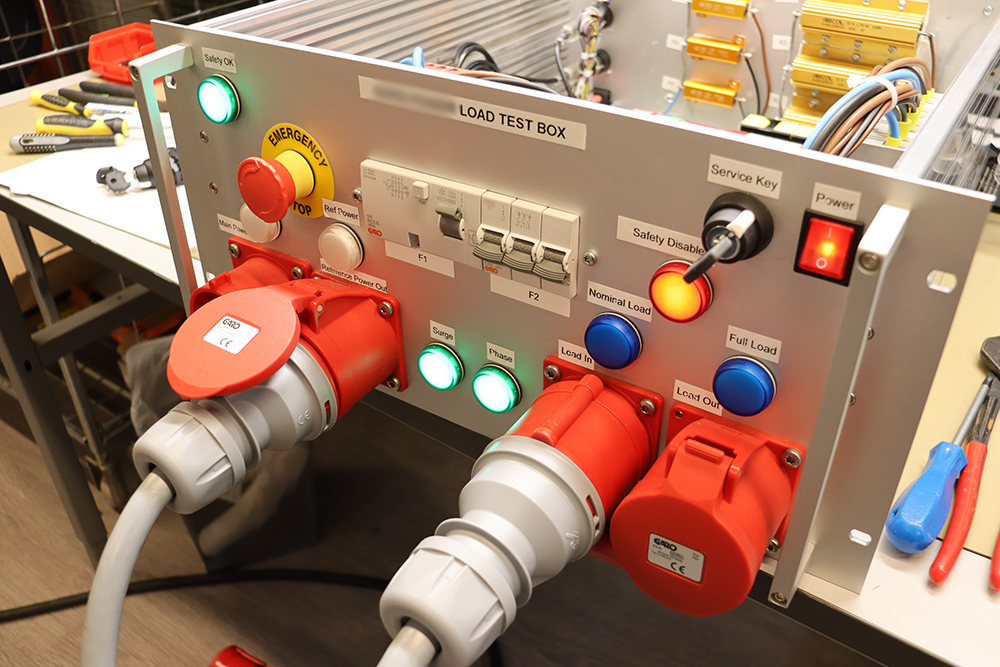

Typically, the finished product comprises multiple circuit boards, wiring, electronics, and other components. While the circuit boards are already tested and approved through a PCBA (Printed Circuit Board Assembly) test, the EOL test ensures that all remaining components are correctly assembled. These systems often feature wiring to connect with the product, cameras to verify the placement and functionality of buttons and LEDs, and mechanical mechanisms to press buttons and activate various functions for thorough validation.

Advanced products may require additional connections, such as compressed air, vacuum, or water. It’s common for operational testing to be conducted during the EOL test, where the product is powered on and evaluated under realistic conditions.

In an EOL test, we rigorously verify the product’s functionalities and ensure that all components meet the specified requirements. We design, build, and customize the test system to align with your unique needs, ensuring it performs precisely to the established specifications.

Reliable and flawless products

The process from requirements to delivery

Requirements Specification

We collaborate to create a comprehensive requirements specification for your EOL test system, ensuring your finished products comply with all functional and safety standards before leaving the production line. This specification covers critical tests, including functionality, safety, and user interface checks. The system is designed to manage high throughput efficiently, quickly detecting defects without disrupting production flow.

Quotation

We offer a clear and comprehensive quotation for your EOL test system, customized to your specific requirements. The quotation includes details on cost efficiency, long-term operation, and maintenance. We carefully assess potential suppliers to deliver a system that meets your current needs while being scalable and adaptable to future production challenges.

Order

Upon approval of the quotation, we launch the EOL test system project. A detailed order is prepared, outlining delivery schedules, quality standards, and integration requirements with your existing production line. The project encompasses all key aspects, including installation, training, and ongoing support.

Procurement

In the procurement phase, we source all equipment and technology required to construct your test system. From advanced testing instruments to automation solutions, we ensure every component is of the highest quality and fully compatible with your production setup. This proactive approach eliminates potential installation challenges and guarantees smooth operation from day one.

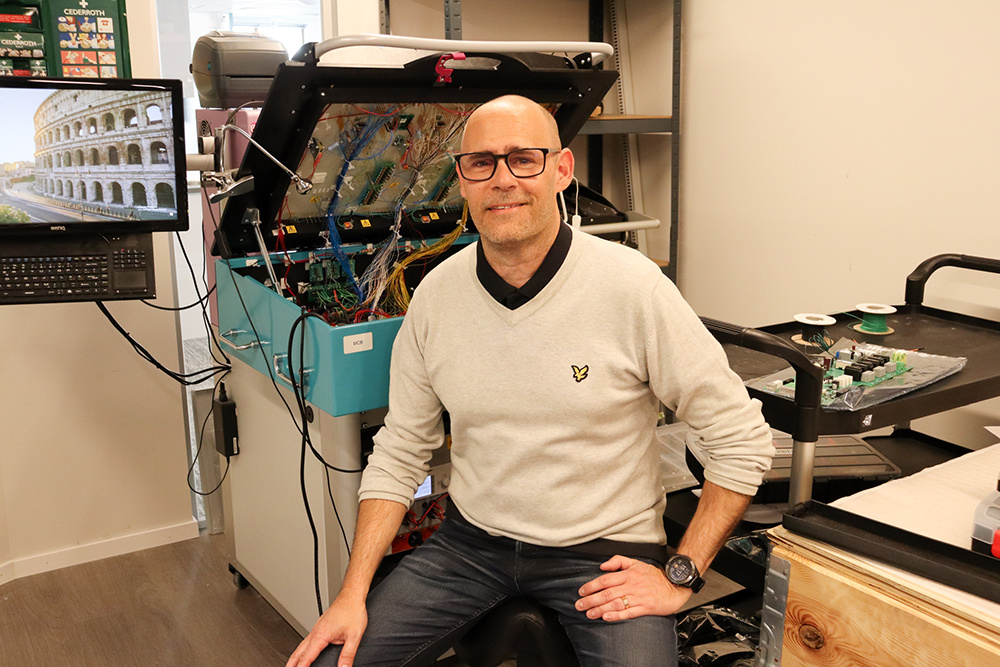

Construction

We build your test system with an emphasis on reliability and efficiency. Seamlessly integrated into your production line, the system is designed to handle high volumes without causing bottlenecks. During the construction phase, ongoing checks and tests ensure the system meets your specifications and is durable enough for long-term, intensive use.

Software Development

The software is designed to automate the entire testing process while delivering instant feedback. It efficiently handles large volumes of data and identifies defects with precision. Detailed reports are generated to help you analyze trends and uncover opportunities for improvement. With its flexible design, the system can be easily updated to adapt to evolving needs and technologies.

Verification

The verification phase is critical to ensuring your EOL test system operates at peak performance in a real production environment. It undergoes testing under diverse conditions and scenarios to validate its ability to detect defects quickly and accurately. Any required adjustments are made promptly to optimize performance. All verification processes are meticulously documented and form the foundation for final approval.

Delivery

After successful verification, the system is delivered and installed at your production site. This process involves integration with existing workflows and system configuration to ensure seamless, efficient operation. Final on-site testing verifies that everything functions as expected. We provide training for operators and maintenance personnel, equipping them to use the system effectively and interpret test results, ensuring sustained product quality and production efficiency.