Production

PCBA Test System

A PCBA test system verifies the proper functionality of all circuit board components, ensuring manufacturing errors are prevented before production.

Provide Your Information

Enhancing Product Reliability and Quality Assurance

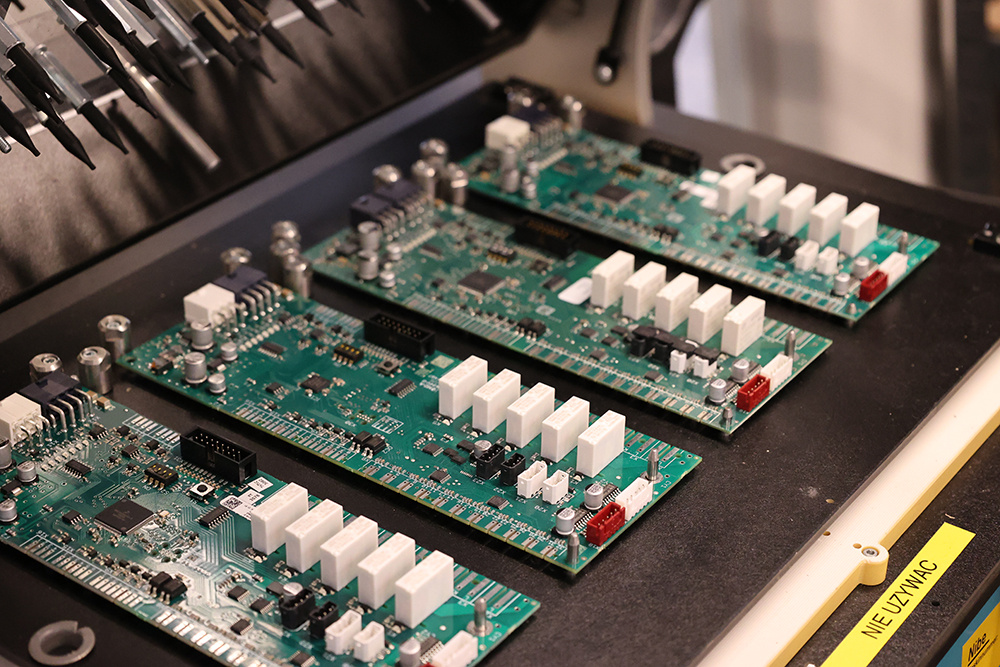

A circuit board test system is essential for production testing, ensuring that all functions of the PCBA (circuit board) operate correctly. Faulty or poorly manufactured circuit boards can lead to production errors, increasing costs due to time-consuming rework or repairs. This makes the testing phase a critical step in the manufacturing process.

A circuit board contains numerous electrical components, making it essential to detect any faults that could prevent it from functioning as intended. Circuit board testing identifies issues early in the process, helping to avoid costly errors later.

We design, build, and customize test systems to meet your specific requirements, ensuring they perform in line with the defined specifications.

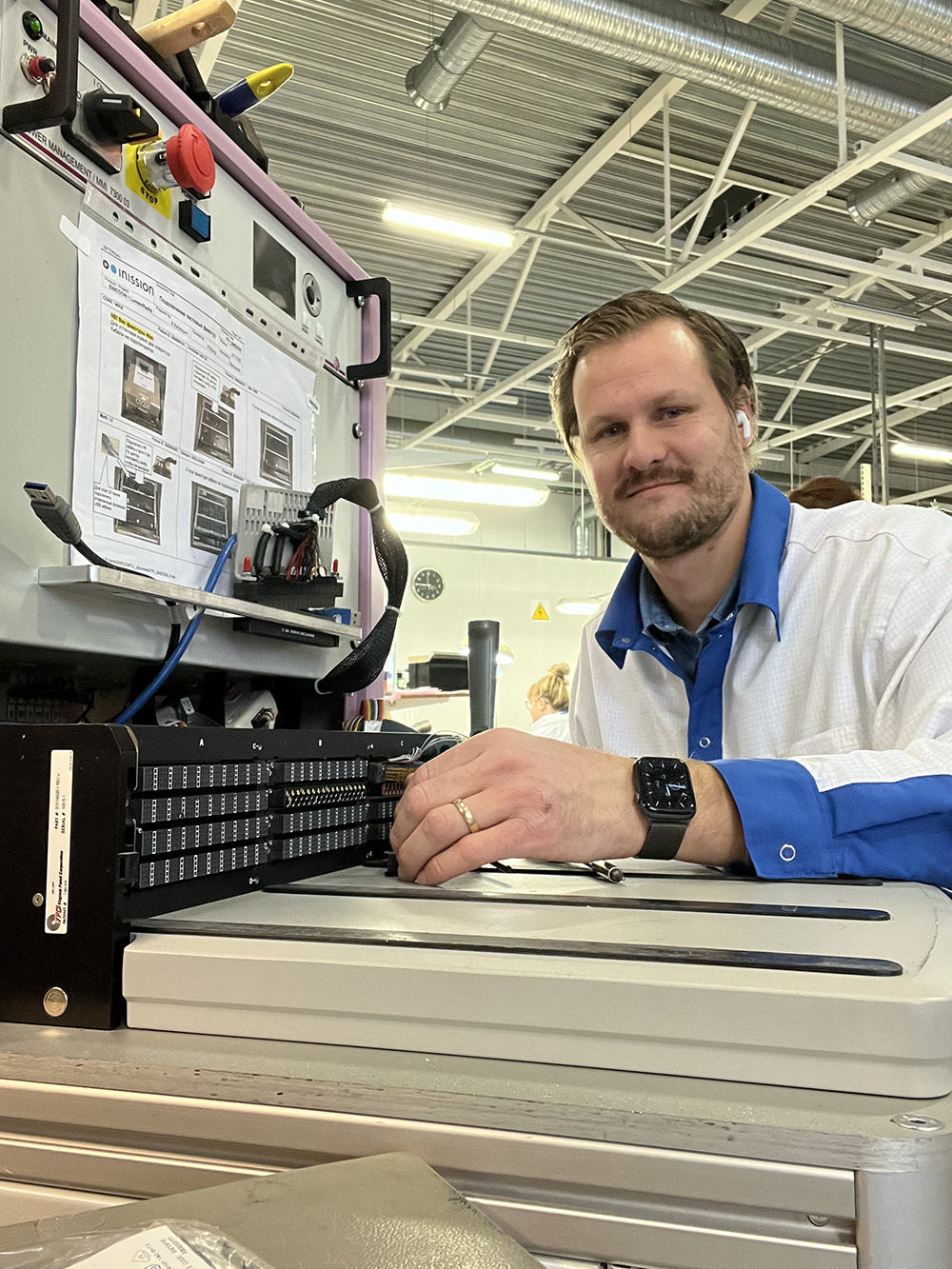

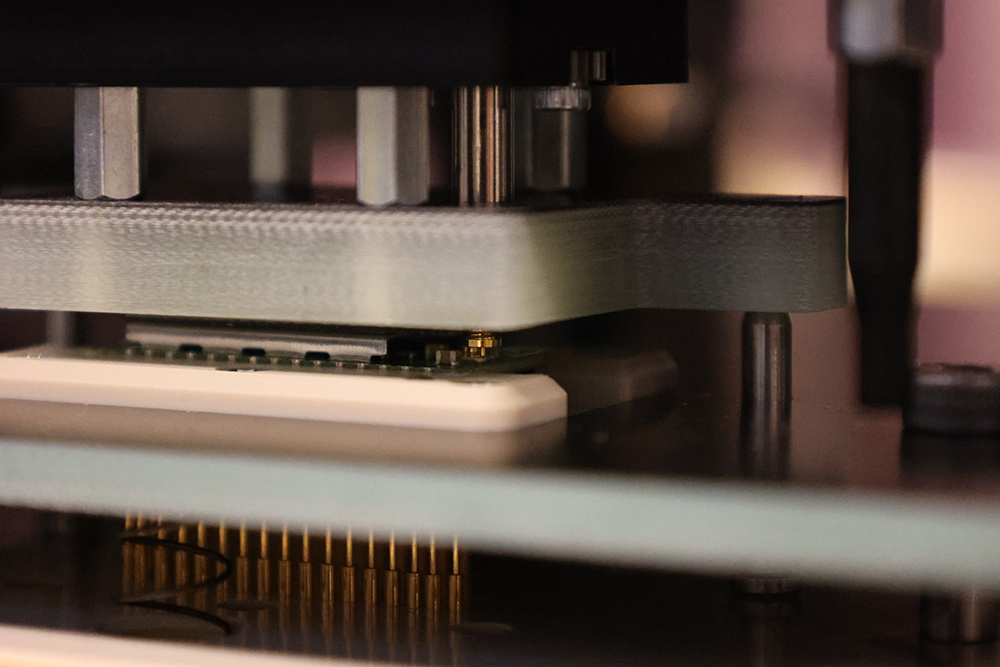

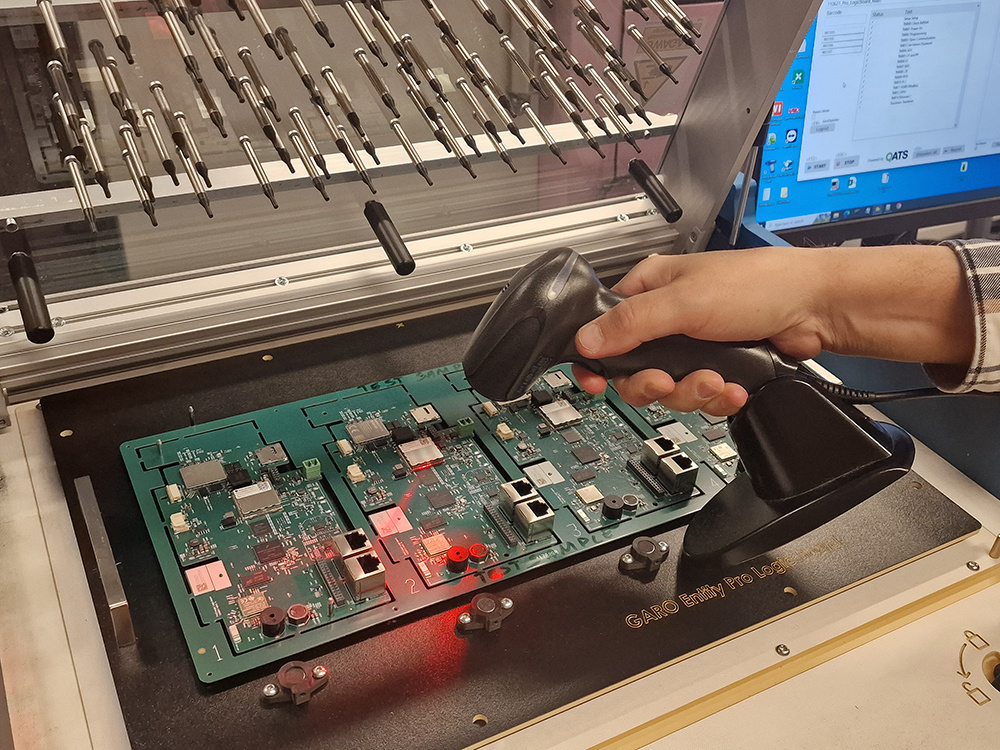

To connect the test equipment to the product, a test fixture is typically used. When the fixture is closed, spring-loaded pins establish a connection with the circuit board. The test setup includes the necessary instruments and electronics to test your specific product. A computer equipped with a test application then automates the testing process and stores all results in a database for analysis and traceability.

Based on your needs

The process from requirements to delivery

Specification Requirements

We work collaboratively to define the technical specifications for the test system, ensuring that the PCBAs meet the highest quality standards and perform flawlessly. Key test parameters, including electrical integrity, signal transmission, component placement, and environmental durability, are carefully addressed. The system is designed to accommodate various PCBA formats and efficiently detect defects, balancing precision and speed.

Quotation

We provide a clear, detailed quotation customized to your specific PCBA testing needs. This includes hardware, software, and integration with your existing manufacturing processes. Our goal is to deliver a flexible, cost-effective system that meets your standards for precision, throughput, and long-term reliability.

Order

After you approve the quotation, we start developing a test system tailored to your requirements. This includes specifying everything from test fixtures and fault detection software to the components needed for a dependable solution.

Procurement

We manage the procurement of all equipment and technology required to build your test system. From premium-quality probes and test jigs to software licenses, every component is carefully sourced to ensure precise testing and seamless integration with your production line. Our priority is delivering the highest quality at every stage.

Construction

We design a robust test system capable of handling high testing volumes with consistent accuracy. By integrating hardware and software into a cohesive unit, the system is tailored to meet your specific PCBA testing needs. Any challenges encountered during development are promptly resolved, ensuring a reliable and efficient solution.

Software Development

The software is designed to deliver an automated, reliable testing process with accurate data collection. It identifies and reports errors with exceptional precision while offering flexible, customizable reporting options. Seamlessly integrated with the hardware, the software ensures a smooth and efficient testing workflow. Additionally, it supports future updates, keeping the system aligned with advancements in PCBA manufacturing technology.

Verification

We conduct thorough testing of the system on various PCBA types and under different conditions to validate its performance and ensure it detects defects and deviations with maximum accuracy. Any necessary adjustments are made during the validation phase to align the system with your requirements, and comprehensive documentation is provided for easy process tracking.

Delivery

Once the system is complete, we deliver it directly to your production environment. Our team manages installation, integration, and final on-site testing while providing training for your staff to ensure efficient operation. The result is a dependable system that enhances product quality and optimizes your production process from day one.