As product development becomes increasingly complex and demands for quality and efficiency rise, modular test systems play a crucial role in ensuring scalability and flexibility. By breaking down the testing process into independent modules, test engineers can quickly adapt tests to new requirements or product variants without having to rebuild the entire system. In this article, we delve into the technical aspects of modularity and scalability and go through how they work.

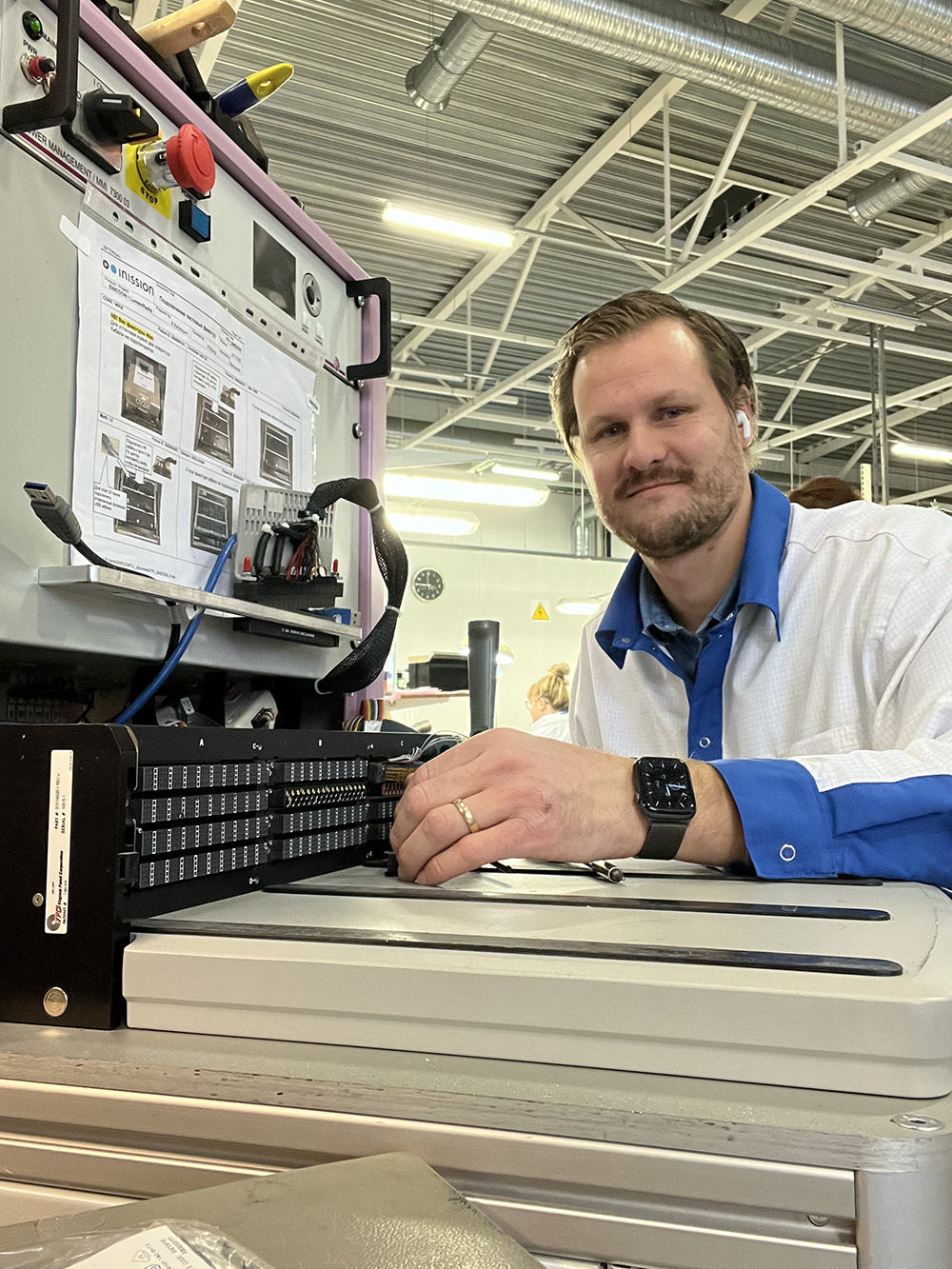

Modular test systems in practice

A modular test system consists of a series of interchangeable components that can be combined in different ways depending on test requirements. These components may include:

- Test hardware: sensors, measuring instruments, and signal generators that can be connected and replaced as needed.

- Software modules: programs that manage test cases, automation, and data analysis.

- Communication interfaces: flexible protocols such as usb, ethernet cables, or wireless connections that enable integration with different systems.

- Data collection and analysis tools: Systems that gather and analyze test data to identify anomalies and patterns. Our QRM tool stores and analyzes test results, ensuring traceability and version control while integrating seamlessly with IT infrastructure to predict failures and improve production statistics.

This modular structure allows new components to be integrated easily without disrupting existing tests. As product requirements change, the test environment can be adjusted with minimal effort.

Scalability in test systems

scalability refers to the ability to expand and adapt the test system based on development needs. this can involve:

- Increased test capacity: as production volume grows, additional test stations or parallel test flows can be added without needing to rebuild the entire system.

- Support for multiple product variants: a modular system enables quick reconfiguration of test sequences to accommodate different versions of a product.

- Automation and remote monitoring: centralized solutions allow test systems to be remotely controlled and optimized in real-time. our QTM tool facilitates synchronization, updates, and remote monitoring of test stations.

- Integration with CI/CD processes: test systems can be linked to continuous integration and continuous deployment (CI/CD) to accelerate development cycles.

Application examples

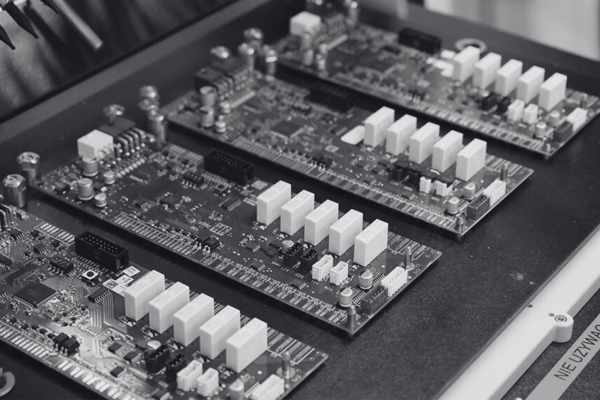

Electronics development

in the electronics industry, modular test systems are used to test circuit boards and components. by swapping test fixtures and software modules, the same test system can be utilized across multiple product generations.

Automotive industry

car manufacturers use scalable test systems to verify the functionality of vehicle electronics, such as sensors and driver assistance software. by adding new test modules, they can accommodate updates and evolving requirements.

Medical technology

in the medical technology sector, testing is critical for meeting regulatory requirements. modular test systems enable quick adaptation to new medical devices and standards without the need to develop entirely new testing systems.

Summary

Modular test systems create a flexible and scalable testing environment that can be tailored to product development requirements. By investing in a modular and scalable test system, you can reduce development costs, accelerate testing, and ensure quality in your products.

%20(1).jpg)